Weighing in the pharmaceutical industry

High-precision weighing solution in hygienic design enables weighing of mobile containers

Key facts

A top pharmaceutical company commissioned the Logica Progetti Company to build a trolley-mounted, 350-litre capacity tank for the production of pharmaceutical syrup. The specific application created the need for a precise, reliable, hygienic and safe solution during handling phases. Minebea Intec was chosen as a key partner for the weighing system.

Application & Product

Pharmaceutical syrups are produced at the end customer’s facility.

- Weighing module Novego

- Cable junction box PR 6130

- Weight indicator X3

Customer benefits

- High precision and process reliability

- High resistance to transverse forces when handling the wheeled system

- The hygienic design ensures quick, efficient cleaning

"Minebea Intec’s weighing module Novego guarantees maximum measurement precision, even when using mixers. We would definitely recommending buying it to others!"

Livio Cornelli and Valerio Spino

(Managers and Owners), Logica Progetti srl

The Logica Progetti Company was commissioned to design and manufacture a 350-litre mobile tank for the distribution of pharmaceutical syrup with the following specifications: vertical construction in internally polished AISI 316 stainless steel with a satin finish on the outer walls, equipped with an inverter- driven magnetic stirrer on the bottom, manual sanitary discharge valve and a hatch with a grill and micro sensor safety switch.

All of this is mounted on three stainless steel legs equipped with compression load cells and an anti-tipping device.

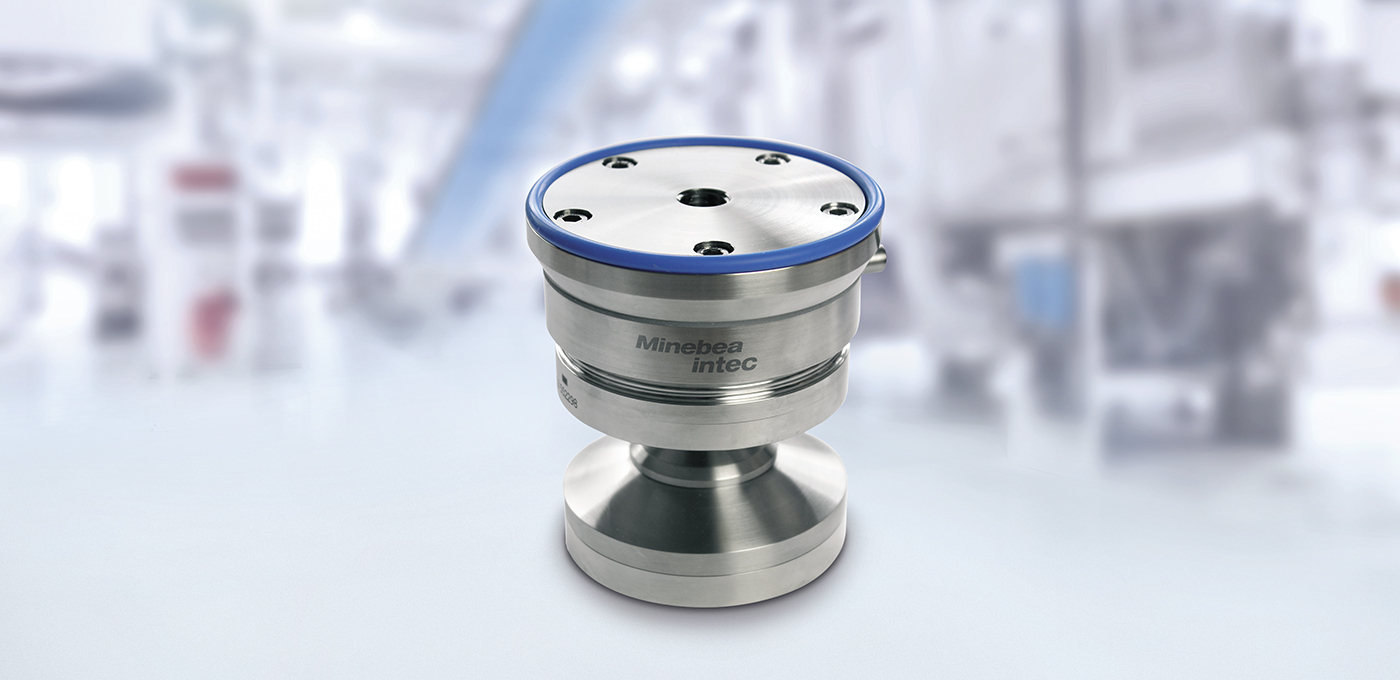

To supply the load cells, Logica Progetti relies on Minebea Intec’s weighing module Novego. In addition to being easy to install on the mobile weighing system, this module ensures that the required measurement is accurate, and above all, allows for easy, residue-free cleaning to achieve maximum sterility.

The scope of delivery specifically included three 500 kg capacity C3-class weighing modules Novego, including an adapter plate PR 6061/00S and a rack mounting base PR 6061/02S. The Novego cells are connected to the weight indicator X3 (PR 5410/00) by means of the stainless steel junction box PR 6130/34S installed on the front of the electrical switch panel cabinet, mounted on the trolley. The indicator PR 5410 controls the start-up and stop of the magnetic stirrer using digital contacts.

The weighing module Novego is able to reliably absorb lateral forces, thus ensuring maximum measurement precision, even when using mixers.

In addition to supplying equipment, Minebea Intec technical staff also conducted all testing and calibration tasks on site at the Logica Progetti Company (SAT), as well as at the end customer’s facility (FAT).

Mediacenter

| Category | File Name | File Size | File Type | ||

|---|---|---|---|---|---|

| Best Practices | |||||

| Best Practices | Best Practice // This high-precision weighing solution with hygienic design is winning over the pharmaceutical industry | 1,95 MB | |||