Avio

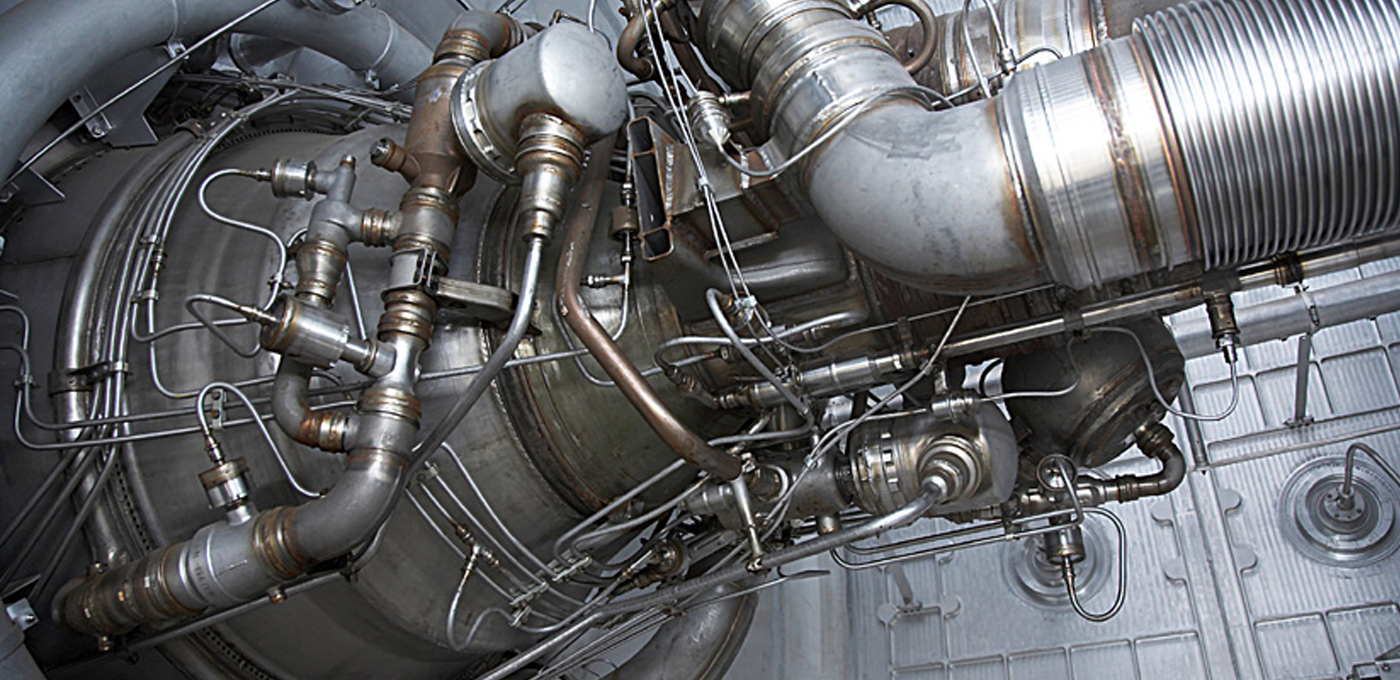

Ensuring ATEX compliance for a leader in the aerospace sector

Key facts

Avio’s manual batching equipment is required to comply with the European ATEX directive, in order to operate in spaces with an explosive atmosphere. When ATEX standards were updated, Minebea Intec stepped in and provided innovative parts for its manual batching system.

Application & Product

Minebea Intec provided two ATEXcertified platform scales and weight indicators and an additional controller for the safe zone operated by a bespoke customized software solution.

Customer benefits

- Compliance with new ATEX standards

- Resolutions of 15.000 d and 30.000 d

- Weighing ranges of 3.000 kg/200 g and 60 kg/2 g

- High connectivity with existing systems

As a producer of propellants for the aerospace industry, Avio is required to comply with the ATEX health and safety standards for electrical and mechanical equipment operating in environments with an explosive atmosphere. The ATEX directive has a detailed risk-based classification for work spaces and covers explosions from gases and solid dust.

Following a routine internal audit, Avio discovered that the manual batching instrumentation currently in use was not compliant with the recently-updated requirements.

Avio had worked with Minebea Intec previously for the supply of a mixing system for rocket fuel. It therefore approached Minebea Intec again – along with other providers - for a weighing solution suitable for ATEX zone 1, the workspace with the second highest risk of explosions.

Minebea Intec was chosen for its ability to provide not only new equipment but a complete solution comprising of hardware and software.

The ATEX-certified equipment included two weighing platforms Combics® with resolutions of 15.000 d and 30.000 d, and ranges of 3.000 kg/200 g and 60 kg/2 g, plus a programmable weight controller Maxxis 5 as well as two localized panelmounted remote displays PR 5110 for the mixing process. For these units, Minebea Intec’s local engineering staff developed a software solution to create the manual recipe database, execute the manual recipe and allow a wide variety of data inputs via a standard keyboard. This data is then transmitted to the PC via a Profibus interface.

Additionally, another terminal was needed for the safe area, to allow users to interact with the manual recipe databases, connect via Ethernet with a printer and a PC and store manual batch reports. Within the safe area an electronic cabinet was supplied which housed each two intrinsically safe interfaces PR 1625 and PR 1626.

Minebea Intec went beyond the immediate need of the customer to comply with current health and safety requirements and over-delivered by also increasing the connectivity and efficiency of Avio’s manual batching operations.

Mediacenter

| Kategoria | Nazwa pliku | Rozmiar pliku | Typ pliku | ||

|---|---|---|---|---|---|

| Best Practices | |||||

| Best Practices | Best Practice // Ensuring ATEX compliance for a leader in the aerospace sector | 948 KB | |||